Description

Belt lift tables

Durability and versatility!

First of all, belt lift tables are dedicated to the pharmaceutical, chemical, cosmetic, food and automotive industries.

In addition, its versatile use makes the work in your company easy, pleasant and above all ergonomic.

Therefore, regardless of the industry, the belt lift tables will allow you to increase the safety of your employees, quickly locate any malfunction, and it will enable easy repair and replacement of parts.

Undoubtedly, this device is a proven alternative to hydraulic scissor lift tables.

All because of its simplicity. Surely, by using the belt lift tables you minimize the risk of downtime on your production line, hall or warehouse.

What is more, it takes less than 15 minutes to replace parts, belts or repair faults. No employee needs special training.

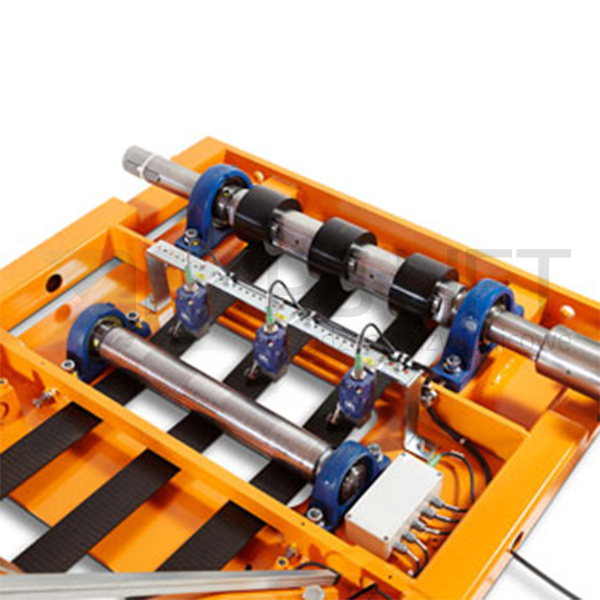

Each belt is monitored separately. In addition, the presented lift table works even when one of the belts break.

In addition, a great advantage of the belt lift table are custom-made platforms. As a result, whatever your needs are, you can always adjust the belt lift platform, for example, to the production line.

Examples of platform designs:

- special openings/ wholes for non-standard components coming off the production line,

- stainless steel versions – particularly important in the food and chemical industries,

- tear plates versions – to prevent cargo from rolling,

- platform cut-outs – especially those used to lift e.g. engines or body parts,

- additional grips – to lift on equipment or wheel axles,

- reinforcement of a full platform.

What else do you need to know about the belt lift table?

- lifting heights up to 6 000 mm,

- lifting speeds of up to 600 mm/s,

- load capacity up to 12 000 kg,

- safety factor >=10,

- use of an inverter: a gentle start allows for a smooth lifting and lowering of the lifting table,

- each belt is made of steel wire ropes with a polyurethane casing,

- the belts are manufactured by Brugglifting, a company specializing in the production of ropes for passenger lifts,

- full steel profiles,

- easy access to replacement parts,

- maintenance-free bearings,

- long service life of rollers and running rails,

- various platform dimensions, additional options available on request.